As head Farrier for the Great British Endurance team and one of only three farriers chosen for the Beijing Olympics, Kelvin Lymer is the Christian Louboutin of horse shoes, the problem is, his customers are generally to be found wandering in the most inhospitable places and therefore he knew he needed to design and build a one piece mobile forge and workshop, operated by

heavy duty slides, that could take him into the wilds.

Being a farrier means I need to be out and about," said Kelvin. "It also means I need to carry a huge amount of kit around with me. The only option was to carry this equipment in a vehicle strong enough to manage such heavy loads, whilst having the 'off-road' capabilities to access the most inhospitable terrain."

Having chosen a Landrover Discovery 4, a bruisingly big brute of a vehicle that sports a 3.0 litre, 255hp diesel engine with a four corner air suspension and Landrover's unique Terrain Response as standard, the next problem was the design of the stainless steel pod and the

sliding movement to extend and retract it from the vehicle.

With the help of the boys from Stainless & Alloy products Limited, headed up by Jeremy Hughes-Hubbold, the pod needed to be capable of being slid from the back of the vehicle and then 'unfolded' to deliver a fully operational forge. Space was always the biggest problem for the team, closely followed by the load capacity of the pod, but with over 30 years of experience in

"It was like," confirms Jeremy, "Squeezing 10 gallons of water into a single pint."

The pod, made of stainless steel is designed to house all the kit a farrier might need, including a forge, an anvil and grinding stones to name a few and to house it all in one, took a lot of trial and effort, but once designed, the next problem was to make the pod retractable. That's when the team decided to contact

Chambrelan UK, manufacturers and distributors of heavy duty slides and sliding systems.

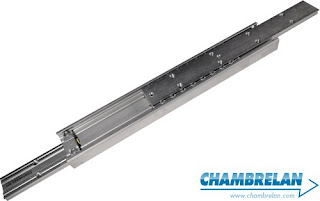

Chambrelan advised the only slide capable of carrying these extreme loads was the E1700 slide, a zinc coated, three beam nested slide, which uses reinforced ball bearings to deliver a soft and smooth sliding 100% extension. Easy to fit and easy to maintain, the E1700 is one of the preferred heavy duty slides used by the defence and emergency services and therefore has a good track record and pedigree.

Suffice to say the project was an enormous success and Kelvin is now designing and building these pods for other farriers.

For more information on a full range of Chambrelan's heavy duty slides and linear rails please visit

www.chambrelan.co.uk